Heart patients meet their valve makers at Edwards Lifesciences

- Share via

Before Costa Mesa resident Lloyd Spencer was diagnosed with a heart disorder in November, he tended to the 175 bonsai trees in his backyard every day.

But his condition — severe aortic stenosis, which occurs when the heart’s aortic valve narrows, obstructing blood flow from the heart to the rest of the body — kept him away from his garden, said his wife, Margaret.

On Friday, Spencer, 95, met the team that kept his heart beating and helped him return to his bonsai trees.

He and about 50 others who have had heart valves replaced with artificial ones arrived at the Edwards Lifesciences headquarters in Irvine for the company’s 2016 Patient Day.

For more than 50 years, Edwards has been developing devices for people with heart disease.

“A day like this not only brings meaning to the work we do but brings the patient’s story to life,” Edwards Chief Executive Mike Mussallem said. “A patient’s voice can get lost in this big healthcare system sometimes. We need to empower them.”

The Irvine headquarters’ valve assembly room has specialists who hand-sew the components of heart valves together. The pieces include cow tissue, cloth, thread and a cylindrical metal frame. Valves can be up to 29 millimeters (1.14 Inches) wide.

Making one valve takes a team of about 20 people seven to 18 hours, according to Edwards’ production manager, Guillermo Cardenas.

Patient Day welcomed people from Orange County, Los Angeles, Texas, Florida, Canada, Singapore and other locations who all attended with the same mission — to meet the team members who sewed their heart valves.

Each valve has a serial number that helps the company identify who helped make the valve and who received it. This enables Edwards to find the patients, invite them to Patient Day and have them meet the specialists who made their valves.

The first Patient Day was held last year.

On Dec. 15, Spencer received a transcatheter heart valve that he calls his Christmas present.

As he walked into the heart valve center Friday, several team members who worked on his valve were waiting for him.

“You all did a good job,” he told them, greeting each with a hug.

Huntington Beach resident Ken Keefe, 72, also received a transcatheter heart valve made by Edwards.

Unlike valve replacements that involve open-heart surgery, patients receiving that type of valve can have it inserted using a catheter that is moved in an artery up a leg and all the way to the heart.

Once the valve is in place, air is released through the catheter to blow up a balloon at the tip of the catheter and give shape to the valve. The catheter and balloon are then pulled out.

Before Keefe knew of the procedure, he thought he might need open-heart surgery to replace a sewn heart valve he got in 2011 from another company. Doctors told him he’d have a 50-50 chance of surviving if he had the open-heart surgery.

“Because of my husband’s lung issues, we knew it would be very risky,” said Keefe’s wife, Silvia. “We were left thinking ‘Well, where do we go from here?’”

Through Silvia Keefe’s research, the two eventually found information on transcatheter valve replacements.

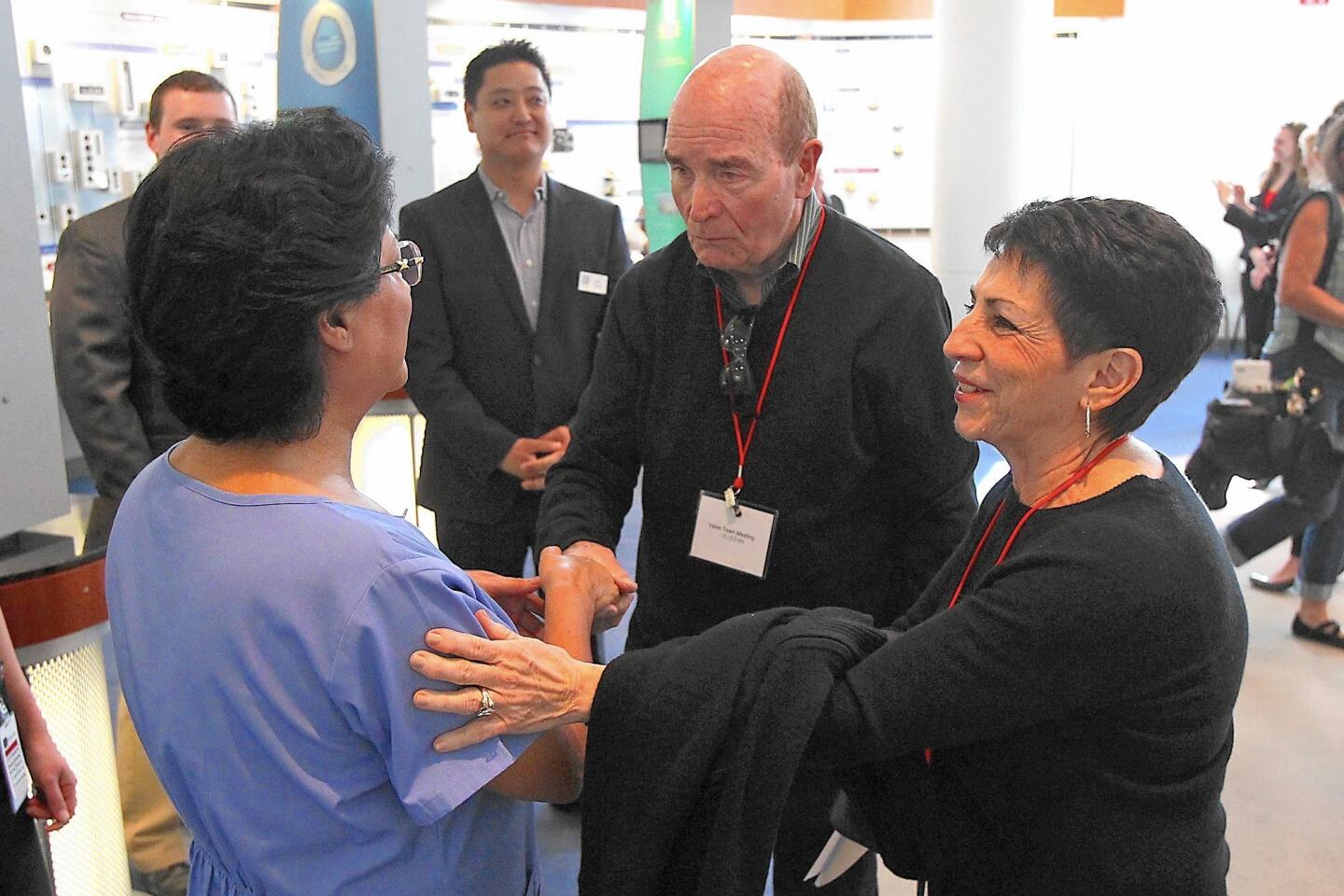

Specialist Sothea Keov, who has sewn heart valves at Edwards for 10 years, made the valve for Ken Keefe’s heart.

When Keov met Keefe for the first time Friday, Keov said it brought her happiness.

“I do this because I want to save lives,” she said. “We make something great that serves someone else.”