Diversification Lets City Shed Its Rust Belt Image

- Share via

ROCKFORD, Ill. — Sitting astride the meandering Rock River, this city looks about as ordinary as a Midwestern cornfield.

But its blandness is deceptive. During the last 25 years, Rockford has played a symbolic role in a high drama: the transformation of the American economy.

An old-line industrial city known primarily for manufacturing machine tools and fasteners, Rockford in much of the 1970s and ‘80s was a Rust Belt town that the economy seemed to have left behind. In 1982, the jobless rate here hit 25%.

Today, the boarded-up downtown storefronts have been refurbished and reoccupied. Thanks partly to computers, old-line industries have become competitive again. The onetime meadows on the east side are blossoming with new businesses, mostly in high technology and services. Suddenly Rockford is a shipping hub for United Parcel Service and and a radio repair center for Motorola.

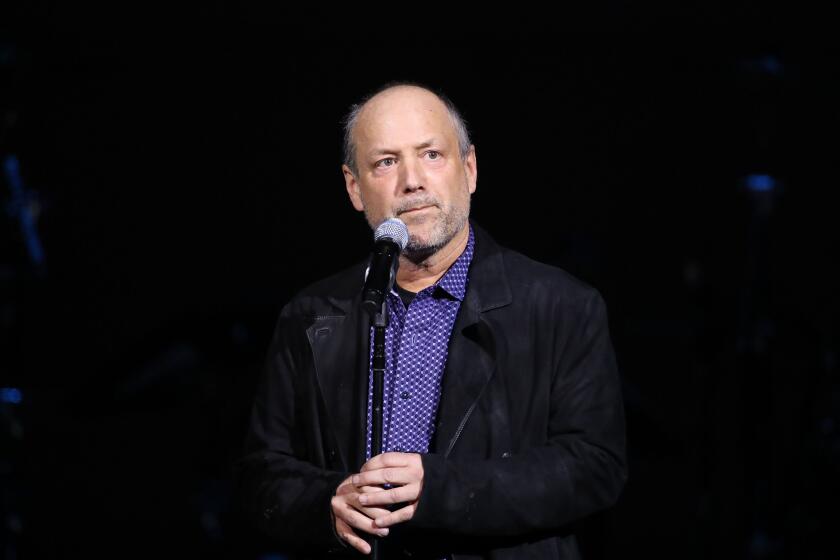

“We’re much more diversified,” said Joseph F. Reagan, executive vice president of the Chamber of Commerce. That leaves the city much better positioned to cope with economic downturns, Reagan said, and its 4.9% jobless rate coincides with the national level.

To some Rockford residents, Joseph Behr & Sons’ scrap yard is symbolic of the city’s renaissance. On a 35-acre plot, the yard contains pile after pile of scrap metal, which the Behr family has collected for generations to melt down and pour into ingots for sale to local manufacturing industries.

Now one corner of the yard deals with a new kind of scrap--discarded circuit boards acquired from personal computers and other electronic equipment around the world. In a tidy converted furniture warehouse, rubber-gloved workers sort the parts and then straighten and recoat the microchip contacts for eventual sale to Third World countries.

“I suppose in one way it’s indicative of our times,” said Richard A. Behr, the soft-spoken man who runs the company.

Many of those who were laid off by Rockford’s heavy industries left town or quit looking for work. Others found jobs with different companies, but for less money. Still others, however, found new, better-paying careers, and a few have gone into business for themselves.

Reagan rattles off a list of businesses that previously would not have located here. “We’ve been running scared,” he said. “This is not so much just about how Rockford will compete as how the entire Midwest will compete.”

The turnaround began in 1988, after Rockford’s often-inefficient and undercapitalized machine-tool and fastener-making companies had been hammered by competition, mostly from overseas. Many cut back to skeleton work forces, laying off large numbers of longtime employees.

Gradually, the companies in Rockford’s manufacturing sector consolidated and modernized to become more competitive. Once back in shape, many began looking to export markets, which they had largely ignored before.

David R. Morgan, president of Precision Group, which makes component parts for diesel engines, said his firm abandoned its system of buying supplies and equipment primarily on the basis of price and now tries to forge partnerships with vendors to ensure quality and “best value”--a standard he believes helps make the firm more competitive.

New businesses also came to town. Dan Johnson, a division manager at Acrux Integrated Solutions, recalled that his firm, which provides consulting services on computers and software, set up shop in 1988 with only eight people, but now has a work force of 70 and is expanding into a different line of services almost every year.

Beverley Kingsley, a small-business consultant at Rock Valley College, said some laid-off workers have opened their own businesses--sometimes selling their ex-employers the same services that they had provided in-house before the company “downsized” and contracted out for the work.

Not everyone involved in Rockford’s transformation has come out a winner.

Wendy Schaible, 34, spent months retraining after the food-processing plant where she worked closed in 1993. Now a practical nurse, she is earning a fraction of what she made before. “It’s really hard,” she said. “I thought I’d be making a lot more.”

Sylvia Gaffney, a Rockford employment counselor, said many of the city’s laid-off workers simply dropped out of the work force and are not counted in the city’s 4.9% jobless rate. The low jobless rate is “not in sync with what people see in the marketplace,” she said.

Rockford is experiencing an employment mismatch, at least at the lower end of the ladder. Business executives and job counselors said many jobs are going begging because firms cannot find qualified people. Some larger companies have begun training new hires on their own.

Many here agree with forecasters’ projections that the nation is headed for a long period of stable growth. But they are uneasy about the prospect of continued uncertainty in the job market and the inability of unskilled workers to find places in tomorrow’s higher-technology economy.

Younger workers are not nearly so uncomfortable.

Kristin Brynteson, a 23-year-old management trainee, said the prospect she may not be spending 27 years with a single company, as her father has, “could be a positive thing” in the long run because it will give her more flexibility and keep her competitive.

“We’re coming across a lot of major changes in the way American business operates,” she said. “There are so many things that are open. I feel that I’m taking on responsibility for what happens to me. Things look pretty much optimistic.”

More to Read

Inside the business of entertainment

The Wide Shot brings you news, analysis and insights on everything from streaming wars to production — and what it all means for the future.

You may occasionally receive promotional content from the Los Angeles Times.