The Valley’s Aerospace Industry Shows Some Signs of Liftoff

Federal budget cuts, recession, earthquake, downsizing, corporate flight and the end of the Cold War--recent years seemed to bring nothing but bad news for the San Fernando Valley’s once-mighty aerospace and defense industries.

If you didn’t read much past the headlines, you might have thought the Valley’s aerospace industry had either shut down by now or had packed up and left, as indeed much of it has.

For the record:

12:00 a.m. Dec. 24, 1998 For the Record

Los Angeles Times Thursday December 24, 1998 Valley Edition Metro Part B Page 3 Zones Desk 1 inches; 26 words Type of Material: Correction

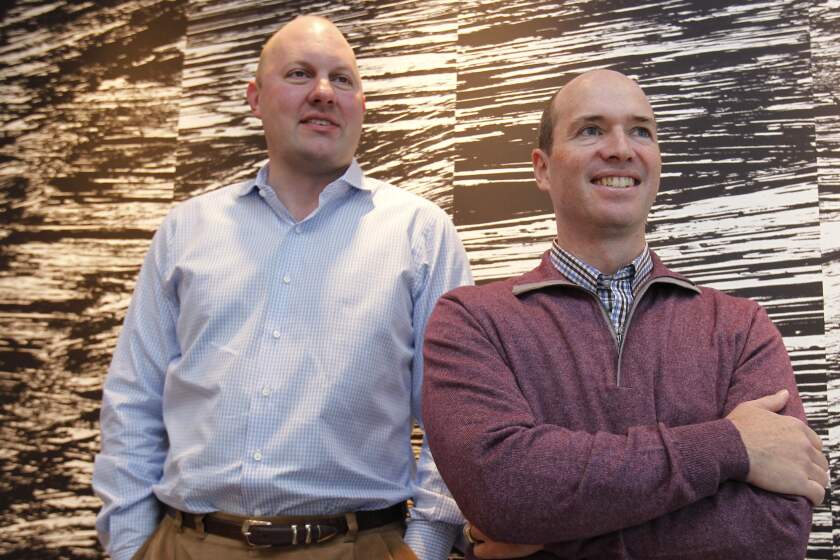

Misidentified--A caption Tuesday incorrectly identified a man on the Valley Business page as Miguel De Leon of De Leon Enterprises Inc. The man is actually an employee of Sierracin Corp.

But in fact, much of the industry is still here. It’s even showing signs of growth.

Through the years, however, the survivors have had to adapt to a changing economy and shifts in the global balance of power. After a Darwinian shakeout, defense and aerospace businesses have been forced to evolve, ranging from a gradual shift in a firm’s customer mix to something resembling total transformation.

Some have stuck with the old--government-funded military and space work--while others have cut loose from Washington’s purse and carved out new business. This is a look at two firms that have taken different paths.

*

*

Miguel De Leon, 42, spent 17 years working at California Electro Fab Inc., a company heavily dependent on defense and aerospace work. He was vice president of operations when the firm went under in 1994.

“The big contracts weren’t there anymore,” he said, adding that things “really bottomed out” at the time of the January 1994 earthquake. In July of that year, a bank was about to auction the assets of the shuttered firm when De Leon saw an opportunity.

Using credit cards and “scraping up a penny here and there” without the aid of a bank credit line, De Leon picked up the assets of the company for “cents on the dollar” and got it up and running again as De Leon Enterprises Inc.

This time, though, the Pacoima company cast a wider net for customers. With its expertise in circuit boards, power supplies, cables and harnesses, it went back to some old customers but also sought more nonaerospace work.

De Leon says the company now gets about 10% of its business from government aerospace contracts (including work for the Jet Propulsion Laboratory). The rest is a diversified mix that includes circuitry in lighting systems for advertising and airport runways as well as components used at airport and courthouse security gates.

About the time De Leon brought his company back from the dead, policy makers were poring over the problem of “defense conversion”--shifting the Cold War economy to peacetime pursuits. For De Leon, the issue was a lot closer to home: “I didn’t have that much time to think about conversion. I just went into it and did it.”

With the help of a $205,000 loan from the Valley Economic Development Center, a nonprofit agency that helps small businesses with loans, training and other programs, De Leon says his firm is now doing more than $2 million a year in sales and has 18 employees. “I’m growing and profitable,” he said.

*

*

Over at Sierracin Corp., change has been less traumatic. The Sylmar-based maker of aircraft windows, cockpit canopies and other components has long had a mix of military and civilian work. The firm tried to remain in the military business, although not to the same extent.

In the 1980s, said Chief Financial Officer Gary Roberts, the mix was around 50-50. Now it’s only about one-third military.

The customer base is also a lot more diversified, Roberts said, with about 70 customers and 150 different programs today, or about a third more than in the ‘80s.

That’s a far cry from the company’s early years, in the ‘50s, when Roberts said “we were tied to Lockheed in a large way.”

Among its military contracts, Sierracin makes canopies for Boeing’s F-15 and F-18 fighters and Lockheed-Martin’s F-16.

On the commercial side, it makes windows for jetliner giants Boeing Co. and Europe’s Airbus, but its biggest customers are makers of commuter and general aviation craft, such as Canada’s Bombardier.

Roberts said the downdraft of the early ‘90s--a one-two punch of defense cuts and a drop in commercial orders--hit the company hard. “We probably lost about 20% of our business between 1992 and 1994,” he said.

But the slump hit other companies a lot harder. “A lot of small aerospace component businesses started out in the ‘50s, and a lot of them ran out of gas in the ‘90s,” Roberts said.

Now, though, Roberts said, business has never been better. “There’s been a real renaissance in aircraft spending, particularly on the commercial side,” he said.

“On the military side, we’re on several programs that are still well-funded by the federal government.”

Roberts said revenue is now running about $80 million yearly--”the highest we’ve ever been, without a doubt”--and has been growing at 15% annually for the past two years. The company has 500 workers at its Sylmar plant and another 85 at a Burbank facility that makes aircraft fittings and seals.

*

*

With up-to-date job statistics lacking for the Valley, it’s not clear how much this “renaissance” has boosted other businesses in the area. But for Southern California in general, aerospace employment has finally stopped its long decline and has even shown a slight upturn. The Los Angeles Economic Development Corp. estimates that after bottoming out in 1995, the aerospace industry in the five-county Los Angeles area added 9,000 jobs through 1997, bringing the total to about 221,000 that year.

In a report this summer, the Los Angeles Economic Development Corp. said “classic aerospace” (which includes aircraft, spacecraft and components), was growing again in the five-county area. “Surprisingly,” the report said, “there have been modest job gains in aircraft manufacturing.”

Jack Kyser, the corporation’s chief economist, said Boeing Co.’s focusing of its space business in Southern California is “probably a positive” for the Canoga Park-based Boeing unit Rocketdyne.

“It’s not the lush life, but you have a lot of things going on,” he said. He also noted the brisk business at Lockheed-Martin’s Skunk Works in Palmdale and Northrop’s B-2 plant nearby. (A Lockheed spokesman noted that employment at the Skunk Works has more than doubled in the past three years, from 2,500 to 5,800.)

As in the ‘80s--though on a much smaller scale--Southern California aerospace is getting a lift from new defense spending.

It’s also getting some political help, said John Rooney, president of the Valley Economic Development Center.

Rooney credited Rep. Howard P. “Buck” McKeon, a Santa Clarita Republican elected to Congress in 1992, with skillfully using his position on the House Armed Services Committee to steer projects to this area, adding that veteran Rep. Howard Berman (D-Mission Hills) has worked well with him.

Before McKeon came on board, Rooney said, “We were ineffective politically because we weren’t on the right committees compared to Georgia and others.”

Local businesses also have high hopes for another federal program now off the ground, the international space station.

But just as Washington has started to smile again on Southern California aerospace, the financial crisis spreading from Asia has sent a new chill through the industry. And this time, diversifying out of defense doesn’t seem to help, because the worst falloff is on the commercial side.

Sierracin’s Roberts doesn’t see any slowdown soon at his company, which he said has already booked most of its window and canopy orders for 1999. But De Leon has seen some slowing in orders from customers who sell to Asia. He’s also getting more cautious, even at the risk of losing business.

When negotiating contracts, he said, “I ask people, ‘Does this go to Asia?’ If they say yes, I openly ask for money up front.”

More to Read

Inside the business of entertainment

The Wide Shot brings you news, analysis and insights on everything from streaming wars to production — and what it all means for the future.

You may occasionally receive promotional content from the Los Angeles Times.