Burnishing a jewelry business

- Share via

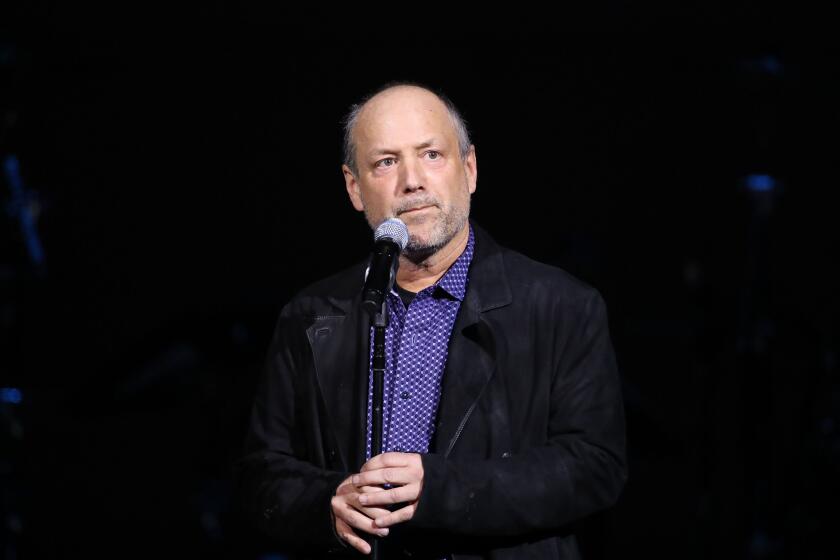

Some people wait years before their creative talents are recognized. Robert Keith waited less than 24 hours.

It was 2005 and Keith, a fashion photographer looking for a new challenge, had just made his first piece of fine jewelry: a gold ring that looked like a miniature version of a ship’s anchor chain.

“I was so proud of it, I put it on my finger and I went down the street the next day to a Starbucks,” Keith said, “and a lady tapped me on the shoulder and said, ‘Excuse me, where did you get that ring? Is it vintage?’ ‘No,’ I said, ‘actually, I made it.’”

Keith landed his first sale that day, using a drinking straw sleeve to size the customer’s ring finger. He was stunned when she readily accepted his price of $3,000, the cost of a ring he had seen at a jewelry store a few days earlier.

Today, Keith and his business partner, Kether Parker, are the primary names behind the rings, bracelets, earrings and other high-end items in the Hoorsenbuhs jewelry collection favored by starlets and rock stars. Despite the Dutch lineage of its name, the jewelry is designed and made in Santa Monica and downtown Los Angeles.

Hoorsenbuhs, which Keith and Parker expect will do about $2.5 million in sales this year, is just a small corner of a big source of manufacturing jobs in the state.

California jewelers export more diamonds than any other state, except New York, in a trade that reached $4.8 billion in 2011. Through the first six months of 2012, exports of jewelry were running just slightly behind another well-known California line of products — aircraft, spacecraft and aerospace parts.

There are about 12,000 jewelry businesses in California that employ as many as 50,000 people, said James M. Orloff of Fresno-based Orloff Jewelers, who wears a second hat as the president of the California Jewelers Assn. Orloff said California is one of the world’s most important contributors to the jewelry world, with much of the state’s industry concentrated in Los Angeles and San Francisco.

“New York is the heartbeat of the jewelry industry. France and Italy start a lot of the trends, but in terms of design and manufacturing, the best comes out of California,” Orloff said. “Everyone wants to see what the celebrities are wearing. Because so many of those celebrities are here, people want to know what the jewelers in California are doing.”

In just seven years, Keith’s jewelry has won over celebrities including Kristen Stewart, Kanye West and David Beckham.

The Hoorsenbuhs line is available in many metals, including gold, platinum and silver, and in any color of diamond, not just clear stones but also black, brown, red and blue. Hoorsenbuhs sells only diamonds that have passed through the Kimberley Process Certification Scheme, an international standard set in 2003 to prevent “conflict diamonds” from war-torn areas from reaching the marketplace.

Even after seven years, the Hoorsenbuhs brand is considered quite young in an industry in which staying power is measured in decades. High-end retailers such as Barneys New York are betting that Hoorsenbuhs will have that kind of long-term marketability.

Farrah Katina, buyer for the Just One Eye shopping site, which operates a boutique in Hollywood, said the Hoorsenbuhs line “has an edge, but it is also very sophisticated.”

“Having a modern appeal and sophistication at the same time is a very rare thing,” she said. “As a brand, I see it lasting for a very long time.”

Hoorsenbuhs — named after a 16th century Dutch trading ship sailed by some of Keith’s ancestors — had an unusual beginning.

Keith was born in Sacramento and raised in nearby Roseville by his father, an art and music teacher, also named Robert, and his mother, Sandra, who ran a nonprofit that helped the mentally disabled. Keith never attended college and received no formal training or apprenticeship in jewelry making.

Keith says it started about 10 years ago as he scoured swap meets, estate sales and yard sales for items to serve as props while he helped out another fashion photographer before taking up the camera for his own work. He was always fascinated by the jewelry.

“The jewelry commanded more respect than almost any other item,” Keith said. That was when he began to teach himself about fine jewelry.

“We really don’t learn much unless we want to,” said Keith, 43, “and I really wanted to learn this. Education is really an easy thing if someone is willing to open their mind to it.”

The second ring Keith made went to his old surfing buddy, Parker, a former actor and fashion model who was working as a salesman at a Mercedes-Benz dealership in Santa Monica.

That job didn’t last long after Parker noticed that a lot of the prospective Mercedes buyers were asking about his ring. Parker was soon carrying photos of Keith’s rings to the dealership.

“We actually started selling quite a bit that way,” said Parker, 40. “And to me this was starting to make more sense than what I was doing.”

It was a good fit. Parker, who joined Hoorsenbuhs in 2007, became the brand’s “ambassador,” focusing on sales and marketing. That freed Keith to focus on design.

Word spread quickly, said Keith, who frequently met new clients on the sets of video or photo shoots and at restaurants and coffee shops.

He jokingly referred to those days as feeling like “drug dealers in the alley. I’d show up and pop the car trunk and say, ‘These are my pieces.’ And they would say, ‘Oh, I have to have this one. I’ve got to have that one.’ I had a ring sizer and a notepad. And I would say, ‘OK, what’s your phone number?’ It had a really organic beginning in that way.”’

Keith’s and Parker’s fashion industry contacts and friends were the source of their big breakthrough. The two were invited to New York in September 2007, where their fashion industry friends promised to send to their hotel anyone who asked about the jewelry.

The friends sent a buyer from Barneys New York, who wanted the entire Hoorsenbuhs line, Keith recalled.

It was a moment filled with giddy irony. Keith and Parker had just landed a $300,000 order from Barneys New York, but they weren’t even sure if their credit cards’ combined limits were high enough to cover their stay at the Mercer, an expensive Manhattan hotel.

Barneys Senior Fashion Director Tomoko Ogura said: “There is something classically beautiful about Hoorsenbuhs jewelry that appeals to women of all ages but there is also a distinct edge.... This balance — in addition to the heritage behind the Hoorsenbuhs anchor they preserve — is what makes the collection special and unique.”

Hoorsenbuhs powered its way through the global recession, and the price volatility of precious metals and gems, with the help of celebrity cachet. Keith said the company’s sales totaled $500,000 in 2009, $750,000 in 2010 and $1.2 million in 2011.

“The only people who can spend $10,000 on a Tuesday afternoon during lunch are people who are recession-proof,” Parker said.

“That’s not the group we target for sales,” said Keith, “but it is the group that has enabled us and our company to survive.”

Keith said the brand isn’t designed for any single income group, profession or age bracket.

“In the beginning, it was just whoever was interested,” Keith said. “We sell to 16-year-old hipsters in Beverly Hills and 75-year-olds from the Upper East Side. We have a really broad range of customers.”

The Hoorsenbuhs line runs from a $700 leather belt with a sterling-silver buckle to diamond-studded bracelets costing more than $100,000.

As a business, Hoorsenbuhs is a tightknit operation, with usually no more than 14 or 15 employees. Friendships and relationships matter to Keith, whose wife, Regina, works as the business manager. His production manager, Gilbert Montoya, has been a friend since third grade.

Every piece of Hoorsenbuhs jewelry plays off of variations on the company’s signature brand image, the three stud links of an anchor chain.

The manufacturing process, Keith said, starts with a hand drawing. Then it moves to a computer-generated drawing. From that two-dimensional beginning, a Hoorsenbuhs ring, for example, begins to take three-dimensional shape with a chunk of jeweler’s wax. It’s a process that has been used for centuries, Keith said.

The center of the wax is bored out to the appropriate size of the ring finger.

A heated wax pen with points of various sizes is used to melt and shape the wax. The thinner the point, the more intricate the work that can be done. If Keith is still not satisfied at this point, he might turn to a three-dimensional computer image for further refinement.

The wax model is then covered in plaster to form a mold. The next step is heating it in a kiln. The wax melts, leaving the hollow mold or form behind. Next is the casting process, the only step that occurs outside the Hoorsenbuhs work rooms. The casting, in which the molten metal is poured into the mold, is done at a facility in downtown Los Angeles.

The rough, unfinished ring then returns to Hoorsenbuhs for the final steps. Those include buffing on a machine that uses brushes of various degrees of hardness and jeweler’s rouge, a carbon compound, to bring out the luster and the detail.

Once the drawing of a ring has been approved, delivery can be made in three to four weeks.

Keith and Parker said Hoorsenbuhs’ next big step will be the release of its first bridal collection this year. It will be sold through Barneys New York at prices from $15,000 to $120,000.

But Keith said his father was wowed by something else he did.

“He’s most impressed by the fact that I made a pair of earrings for the first lady, Michelle Obama,” Keith said. One of the first lady’s fashion consultants had asked Keith to make some jewelry for an event. Keith said he wound up providing “an assortment of items,” including bangles and a pair of hoop earrings. The jewelry, which included about 8.5 carats of diamonds, was later returned to the company, as is customary.

“I just don’t know if she ever wore them,” Keith said.

This is one in a series of occasional articles about California manufacturers.

More to Read

Inside the business of entertainment

The Wide Shot brings you news, analysis and insights on everything from streaming wars to production — and what it all means for the future.

You may occasionally receive promotional content from the Los Angeles Times.