Sailmaker takes a new tack into mask-making

The crew at Ullman Sails Newport Beach creates products to harness the wind, and to prevent the spread of the coronavirus.

The sailmaker pivoted within days of California’s pandemic-driven stay-at-home order in mid-March to start cranking out reusable face masks using tough but breathable technical fabric, keeping its sewing machines humming and its seamstresses from furlough. The uniquely positioned manufacturer went quickly from making a few masks for friends and family to mass-production: more than 4,000 lightweight, moisture-resistant masks so far.

They aren’t rated for medical use, but shop owner Bruce Cooper, who lives in Irvine, is confident in his product for everyday wear. It doesn’t fog glasses. Hold it face-up under a faucet and note that the linen-like liner stays dry. Flip it upside down and watch the hollow for the nose and mouth fill up like a coffee mug.

They don’t last indefinitely, but they’re sturdy.

“We don’t make disposable stuff,” Cooper said, walking between his front office and the room where his identical twin brother, Ken, cuts out the mask components from 3-yard-by-1-yard swaths of cloth. “We make stuff that’s supposed to last years. To last through storms.”

With medical-grade respirators and surgical masks scarce, many people were in DIY territory to help prevent the spread of COVID-19 in the face of rapidly shifting mask guidance and projections of the disease’s severity. Cooper saw a need for people to mitigate the potential health impacts of COVID-19 and for his shop to stay afloat.

In early March, he traveled to Mexico for two regattas, the San Diego to Puerto Vallarta as the spinnaker trimmer aboard the Sapphire Knight and then the MexORC race. The virus had made landfall in the United States, but society had not shut down.

Orange County health officials reported 100 new cases of coronavirus Thursday, revealing a steady upward trend even as restaurants and retailers began reopening Memorial Day weekend.

He returned home March 21 to a markedly different environment.

His girlfriend, Jennifer Monaghan, who works for a major grocery chain, had no personal protective equipment as anxious crowds stocked up on toilet paper and other staples. His elderly parents are at-risk of the worst consequences of the virus because of their age.

The day after he came home, he sat at his home sewing machine stitching together prototypes. He was motivated by his family, and a call from company founder, Dave Ullman, also saying he should make masks. Using a pattern he found online and Evolution Block-It fabric, a synthetic blend used as a car and boat cover, Cooper quickly settled on a winning design.

Two days after he started sewing, he sent his first package to a nephew, David Cooper, a firefighter in the state of Washington whose crew wanted something between their full-face respirators and flimsy disposable face coverings.

Through word of mouth and a well-placed social media influencer — Ullman’s son Jake, an executive at Fox Sports — it wasn’t long before “we couldn’t produce masks fast enough.” Cooper charges $18, a slim margin to keep going, though he will sell at cost to medical professionals, essential workers and older buyers.

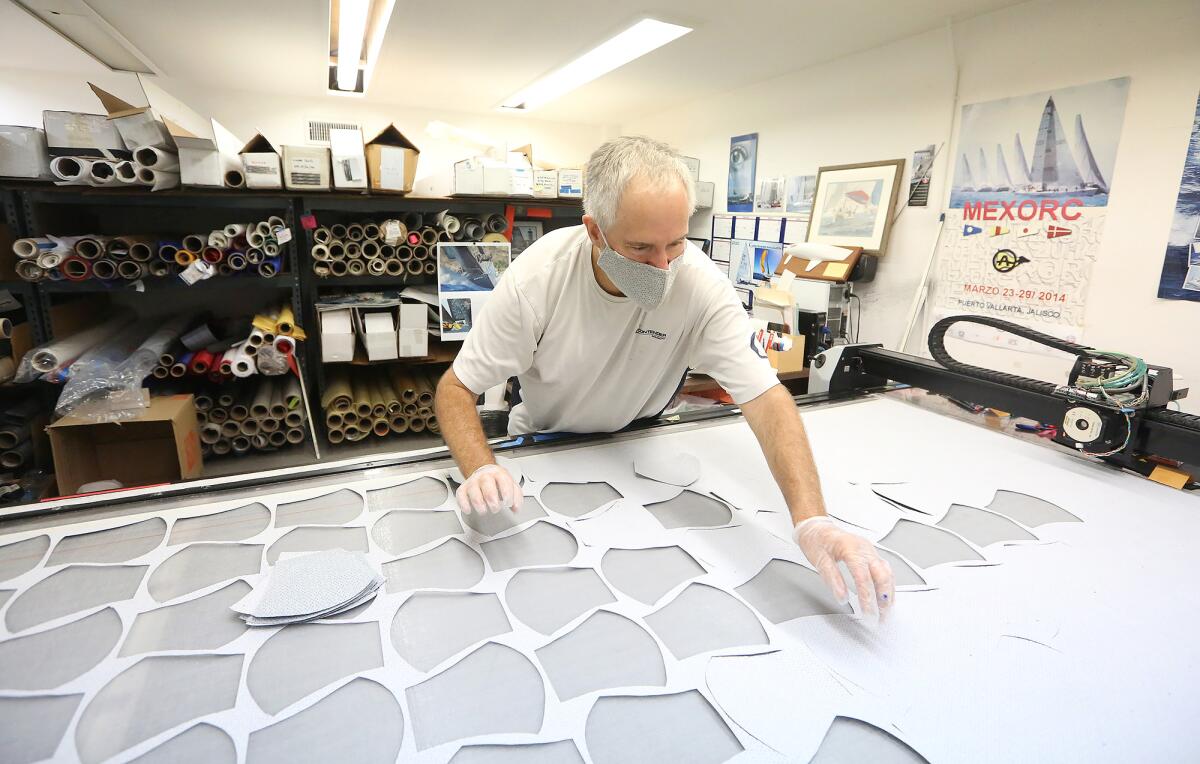

At their loft, as sailmaking shops are called, at Harbor Boulevard and Warner Avenue in Santa Ana (the business got its start in Newport Beach and kept the name after relocating), Ken feeds the pattern into computer software that guides his precision-cutting tools to slice mask halves with hair-splitting precision.

Surrounded by posters of their usual product in action on the open sea, Ken, who lives in Mission Viejo, cuts and collates the halves for seven seamstresses to sew together in the adjoining warehouse.

“I call it Post-It Notes,” he said of the relatively tiny product. He’s used to sails that can be 15 meters long.

If sailing on the open ocean is a well-distanced endeavor, then by necessity and geometry, so is making the sails — laying out an infrastructure that mitigates the risk of working on a production line. The sewing room is an airy, cavernous space where a handful of seamstresses work seated in pits around a raised wooden platform that resembles a roller skating rink, head and shoulders at the surface level several yards apart to efficiently handle sails that could cover the floor of a garage. In a far corner, where an open door lets in the scent of blooming jacaranda, another employee snips elastic for ear loops.

“We don’t make disposable stuff. We make stuff that’s supposed to last years. To last through storms.”

— Bruce Cooper, Ullman Sails Newport Beach shop owner

Cooper said he’s shipped masks to several senior care facilities through the Orange County Health Care Agency’s donation network, to support staff at a field hospital in New York’s Central Park, and to a fellow sailor in Santa Barbara who purchased them for his food-producing agricultural workers. His crew has made 1,000 for the Long Beach Yacht Club, which includes them in to-go meals prepared for members in the club’s restaurant. They also make pleated flat masks in a cotton blend, a common style that home crafters can also make.

Demand has become more manageable recently, allowing the team to take a breather and begin building up stock. Not all cities or private businesses require masks in public, and police have not taken a strong stance on enforcement of mask rules.

And, regular sail orders have returned to Ullman Sails Newport Beach.

But Cooper said masks will be a fact of life for a while.

He went grocery shopping in Irvine, where he was surrounded by varied masks types, and “I felt like a tank walking around with mopeds around me.”

All the latest on Orange County from Orange County.

Get our free TimesOC newsletter.

You may occasionally receive promotional content from the Daily Pilot.