- Share via

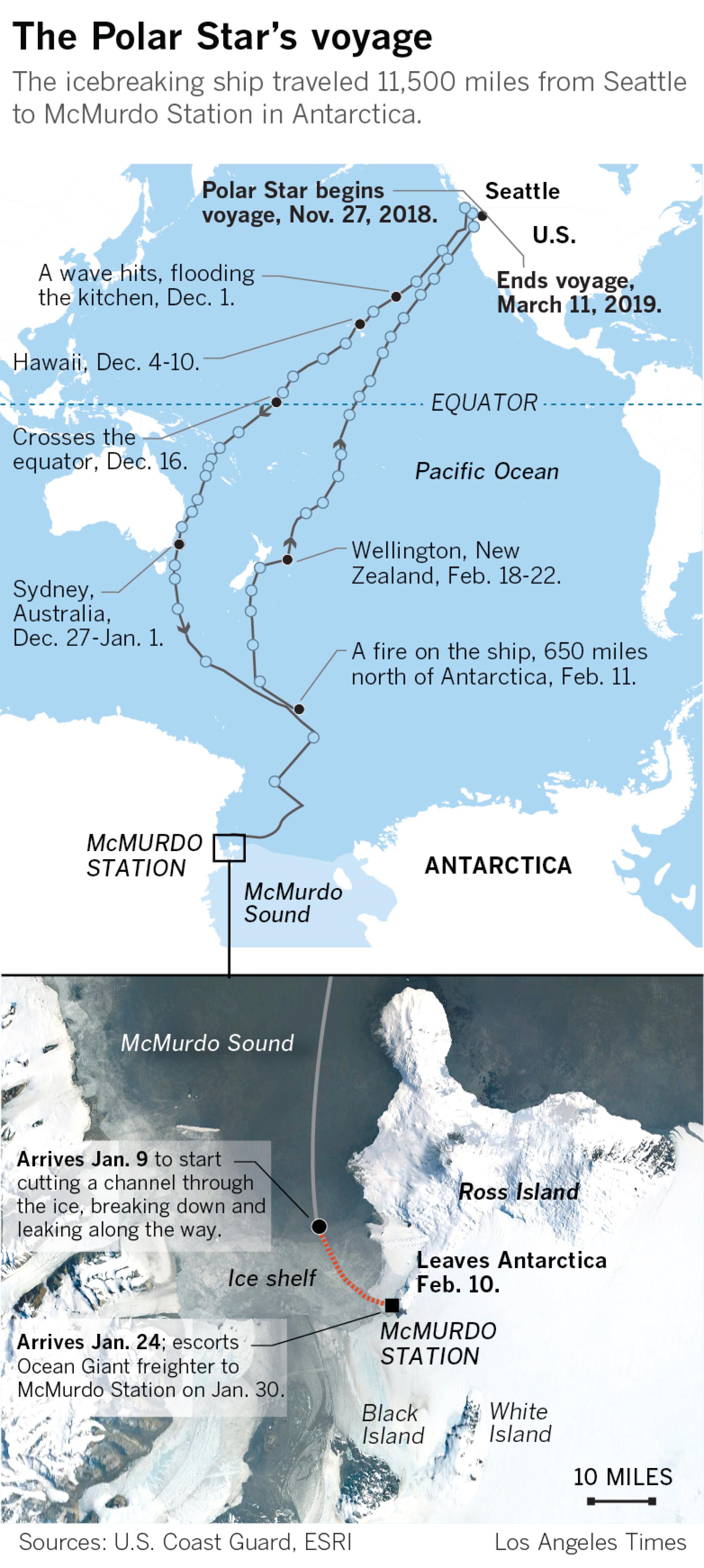

The icebreaker Polar Star was 1,000 miles out of its home port of Seattle last December, three days into its yearly voyage to resupply scientific bases in Antarctica, when a powerful swell hit its bow and flooded the deck.

The ship shuddered.

The roar of the ventilators in the galley quit as Joseph Sellar, a stocky 25-year-old Coast Guard culinary specialist from New Hampshire, watched seawater explode from the ceiling.

He lunged toward a switch to close the overhead vents. With a loud pop, an outlet ejected a purple spark.

“Are we sinking?” asked a petty officer on temp duty from Virginia.

Sellar knew better.

“Calm down,” he said, whipping out his cellphone to record the gusher.

The United States spends $2 billion a day on the most advanced military ever assembled, with more aircraft carriers, fighter planes and nuclear submarines than any other nation. The Pentagon intends to develop a space fleet of orbiting lasers, missile sensors and satellites.

Then there is the Polar Star.

The only U.S. ship capable of bludgeoning through heavy ice, it is the neglected 43-year-old stepchild of the U.S. military-industrial complex.

After decades of abuse, the vessel lists to port, but its sewer pipes drain to starboard, jamming and overflowing toilets. Rust coats decks, hatches and ladders. Lead paint peels from walls marked with warnings of asbestos.

The only U.S. icebreaker that can break through heavy ice is the neglected stepchild of the U.S. military industrial complex. The Coast Guard’s Polar Star resupplies the U.S. Antarctic Research Station and limps home every year.

While Russia will soon have more than 50 icebreakers, the fire-engine-red ship lumbers on as a Cold War relic.

Crew members scour EBay for discontinued replacement parts. A petty officer who used a surfboard repair kit to fix a generator, saving the ship from encroaching ice, received an award from the Coast Guard commandant.

Each time the ship makes the 11,500-mile journey to Antarctica, it falls apart. Turbines quit. Seals rupture. Resistors fail. Then it limps home for months of repairs.

The torrent that inundated the galley Dec. 1 destroyed the top oven, subjecting the crew to cold cuts for a week while a $50,000 replacement was flown to Honolulu, the ship’s next port. Machinery that desalinates water also broke.

As problems went, these were not especially unusual for the Polar Star.

“She’s an old beast, and you gotta know how to run her,” Sellar says. “You can’t just turn the key.”

A reporter and photographer ride from Seattle to Vallejo, Calif., on the Polar Star, which falls apart on its round trip to Antarctica each year.

Research in Antarctica

The sun rises in Antarctica each October and doesn’t set again until February.

It’s the austral summer, the season of science, when more than 1,000 researchers and support staff live at McMurdo Station — a jumble of dorms and dozens of other buildings located on the Ross Sea’s Winter Quarters Bay — and the much smaller Amundsen-Scott South Pole Station 1,000 miles inland.

The population at the two U.S. bases shrinks to fewer than 100 during the southern winter, when darkness sets in and polar temperatures can plunge lower than 100 degrees below zero.

But the research conducted in Antarctica can’t be done anywhere else.

Scientists have drilled down more than 2 miles for ice cores that show how the climate has changed over thousands of years. Research on how emperor penguins endure extreme pressure during deep dives has led to improvements in anesthesia.

The frigid conditions, ideal for some of the world’s most sophisticated telescopes, enabled astronomers worldwide to capture the first photograph of a black hole.

None of this would have been possible without the Polar Star.

It debuted in 1976 as one of the world’s most powerful nonnuclear ships. Six diesel locomotive engines and three gas turbines generate 75,000 horsepower to spin propellers as big around as grain silos.

Engineers at Lockheed Shipbuilding & Construction Co. shaped its hardened-steel hull — 399 feet long and 83 feet wide — like a football, pointed at both stem and stern. With a draft as deep as an aircraft carrier, the Polar Star can rock, ram and reverse through ice up to 21 feet thick.

That’s what it takes to reach McMurdo year after year, carving a path for a freighter loaded with everything the scientists need to survive.

Operation Deep Freeze, as the annual mission is known, has often been brutal, but never more so than in 2006, when massive icebergs clogged the Ross Sea, forcing the Polar Star to ram through a record 97 miles of ice.

The ship made it through just one more season before commanders moved to retire it.

They relied instead on its slightly younger sibling, the Polar Sea — an arrangement that lasted until 2011, when that ship suffered a catastrophic engine failure and the Coast Guard relegated it to a Seattle dock as a parts donor.

A $62-million repair job resurrected the Polar Star, but the years sitting idle meant its machinery and wiring would never be the same.

Oh, the indignities

Two days after the flood that destroyed the oven, engineers smelled smoke coming from an old Westinghouse electrical panel in the ship’s main control room.

Peeling open the metal cabinet, they found the culprit: a burned-out coil the size of a coffee can. Without it, the port propeller was useless.

A backup was nowhere to be found in the ship’s parts shop, which stores 5,000 replacements for items judged most likely to fail. So electricians back in Seattle extracted the identical coil from the Polar Sea and sent it by air to Honolulu.

The Polar Star chugged into Pearl Harbor, using a gas-guzzling turbine usually reserved for ice-breaking. The next day, the ship suffered yet another indignity: Its whistle stuck.

For two minutes, the foghorn echoed across Pearl Harbor.

The journey continues

The Polar Star spent six days in port before embarking again on Dec. 10, its port propeller and desalination machinery working.

Crew members were relieved. But the next day, the desalination unit quit again, forcing the crew to skip laundry and limit showers to two minutes.

Still, the ship lumbered across the equator at a steady 18 mph. Capt. Gregory Stanclik remained upbeat at briefings as he addressed crew members lined up on the rear deck, swaying in unison against the waves.

On Dec. 22, Stanclik made a much-anticipated “swim call,” halting the ship so sailors could plunge into the azure sea 260 miles west of New Caledonia.

But that evening he delivered more bad news: Their paychecks were about to stop.

President Trump had hit an impasse with Congress over funding for his wall along the border with Mexico, shutting down much of the federal government.

With internet service often down, officers authorized extra satellite-phone time. Christmas greetings over scratchy connections gave way to anxious talk with faraway family members of rent bills and loan payments.

If there was any solace, it was the next port. On New Year’s, crew members joined more than a million spectators awed by fireworks that showered Australia’s Sydney Harbor with gold, purple and silver.

The next stage of the voyage — through the Southern Ocean — proved especially rough as massive waves battered the ship.

Crew members rolled from bunks. Dinner plates sailed off tables, slamming against walls.

But at least the ship was moving.

On Jan. 9, it reached the ice edge at McMurdo Sound. The vessel that had loomed large by Seattle’s Space Needle seemed to shrink like a toy boat against the glaring expanse of white.

Seventeen miles of ice, 6 to 10 feet thick, stood between the ship and McMurdo Station.

Plowing through frozen sea

A compartment resembling a crane cab, perched atop the ship 155 feet above the ice, shook violently as Lt. Cmdr. Karen Kutkiewicz gripped engine control levers. At 5 feet 5, she stood on tiptoes on a wooden box.

The rattling of window frames and ceiling tiles competed with the Christian rock playing from her smartphone. Kutkiewicz, 35, wore dark glasses against the fireball of sun that circled the ship every 24 hours.

Slowly, she backed the Polar Star a half-ship’s length. Then firmly, she pushed the throttles from half-speed to full.

The ship’s bulbous prow thrust upward, riding a ledge, penguins scattering in its path. Then it crashed through the ice sheet. Glistening boulder-sized shards broke off, bobbing toward the stern.

On the dashboard, an indicator light flashed red. A black wall phone jangled. “You’re overloading the port shaft,” said a voice from Main Control, deep below decks.

It was a refrain familiar to Kutkiewicz and the other four ice pilots who rotated in three-hour shifts around the clock.

The ship was now a 13,500-ton jackhammer.

What could go wrong?

Four days and 4 miles into the ice, the Polar Star sprang a leak.

Seawater sprayed through a broken fitting into a cramped compartment that houses the shaft turning the main propeller, which drives water past the rudder.

Without a speedy fix to regain steerage, the Polar Star would face a nightmare scenario: getting stuck in ice as the ocean froze around it.

With no other heavy icebreakers in its fleet, the U.S. would have little choice but to rely on foreign help for a rescue.

Crew members figured that if anyone could plug the hole, it would be chief engineer Brad Jopling, the son of a Montana heavy-equipment mechanic. Jopling, 40, never complained about being woken at odd hours by mechanics presenting handfuls of broken parts.

A portable pump slowed the water’s rise while he and his team devised a plan.

Two Navy divers suited up. Laden with ropes, rubber mats and heavy plastic wrap, they were about to descend 30 feet to Polar Star’s idled propellers when a watch officer noticed a different threat: a pod of killer whales.

Two hours later, the divers finally splashed into the water and bound the mats around the leaking prop shaft where it protruded from the hull. The hope was that, wrapped in plastic, the mats would form enough of a seal to slow the flow.

On a second try, they managed to cut the stream to a trickle.

The plan had worked.

Jopling and an assistant crawled back into the compartment, staving off the cold with jokes about working without pay. Crouching in water up to their necks, they used a wrench adapted in the ship’s welding shop to remove and replace the fitting.

“If you don’t mind, it don’t matter,” Jopling liked to say.

But he cared deeply for the ship and worked not just to fix it but to make it stronger.

“You bleed into it, and pour your heart and soul into it,” he said. “All you got to do is get everyone home safe, and make it better.”

The leak and repair had halted the ship for more than 30 hours. Some crew members had seized the opportunity to take in the stark beauty of a continent that had no countries, currency, cities or hotels.

You bleed into it, and pour your heart and soul into it. All you got to do is get everyone home safe, and make it better.

— Brad Jopling

In his stateroom, Stanclik held the crumbling part between his thumb and forefinger. The brittle fitting, an inch and a quarter in diameter, had been mistakenly installed during a previous repair.

It was made of mild steel instead of corrosion-resistant copper nickel.

Cause for alarm

The Polar Star suffered ship-wide power outages twice over the next 11 days. Steel bars meant to stabilize propeller shafts broke so many times that engineers ran out of the 8-inch bolts needed to repair them.

McMurdo sent four more bolts in a helicopter, which set down on the ice because the ship’s flight deck was no longer certified for landings. A crane lowered Jopling in a “man basket” to walk out and retrieve them.

On Jan. 24, the Polar Star finally docked at McMurdo. That night, in light of the Coast Guard’s continued lack of pay, scientists passed the hat for a $1,500 bar tab at the station’s three watering holes.

It was good timing: The federal shutdown ended the next day.

The ship spent two weeks at the base, not counting a jaunt back through the channel to the outer edge of the ice to meet the Ocean Giant. The freighter, loaded with 400 cargo containers, followed just 500 feet behind the icebreaker to prevent the space between them from freezing over.

At the dock, workers unloaded containers stowed with 52,000 chicken breasts, ground beef for 33,000 hamburgers, dough for 123,000 cookies, 18 concrete foundation footers, a tractor-trailer and a construction elevator.

The day before the Polar Star departed McMurdo, Stanclik let crew members walk out on the ice sheet for a few hours. Some played touch football. One group admired seals and an emperor penguin. Kutkiewicz broke out her cross-country skis.

But the sense of peace was short-lived.

On Feb. 11, one day into the trip home, another fire broke out. Then another.

Courtney Will, a damage-control petty officer, was working in the ship’s coffee shop two levels below the main deck when she heard a boom.

“Well, that didn’t sound right,” she said to a co-worker.

Six hundred and fifty miles north of Antarctica, sirens blared.

On more modern ships, crew members can remotely activate sprinkler systems or chemical retardants. Not on the Polar Star.

Will, 25, darted into the ship’s damage-control locker and pulled on a bulky firefighting suit, mask, helmet, boots and an air tank.

She grabbed a thermal imaging sensor and led two other firefighters up two flights of steep stairs. They shoved open a door. The ship’s incinerator was ablaze.

Will elbowed her nozzle man forward. The first blast of water from the hose hit hot metal, unleashing a wall of steam as flames darted toward the ceiling.

Will called for more water. She had to prevent flames from exploding a sludge tank across the room. But she knew that flooding the oil-streaked floor would create more hazards.

“Short bursts!” she yelled.

A shot of purple fire retardant cut through the steam. Another team took a turn.

Two hours later, the fire was out.

As for the future

The Polar Star pulled into port in Seattle on March 11.

Four days later, the Coast Guard announced that a Mississippi company would build a new heavy icebreaker by 2024 for $746million.

It was a major triumph for a branch of the military long neglected by Congress.

Even so, Coast Guard commanders and allies in Congress say the U.S. will need more icebreakers as climate change reshapes the polar regions. Enough ice has melted to open Arctic shipping lanes — at least seasonally — as well as areas that hold rare-earth metals and perhaps a quarter of the earth’s undiscovered oil and gas.

Coast Guard officials say that more ships in the Arctic mean more potential accidents and rescues, more smuggling to interdict, more terrorists to stop, and greater need to assert U.S. sovereignty in the nation’s economic zones extending 230 miles from shore.

They expect the Polar Star to remain in service at least seven more years to accompany the new vessel to Antarctica for two seasons as a backup.

That would make it a half-century old.

And so in April the ship traveled from Seattle to the California port of Vallejo, where tugboats nudged it into a slip and onto blocks. Muddy water drained from around the scarred hull.

Workers swarmed the ship like a pit crew at Indianapolis. They would strip down and rebuild engines and turbines. They’d patch up the desalination units yet again. They’d place the three 85,000-pound propellers on wide-load trucks to haul them 600 miles to Oregon for reconditioning.

They had five months to overhaul the Polar Star for next season.

Production by Jessica Martinez

More to Read

Sign up for Essential California

The most important California stories and recommendations in your inbox every morning.

You may occasionally receive promotional content from the Los Angeles Times.